We offer a comprehensive range of UKAS 17025 approved mechanical, metallurgical, corrosion and analytical testing services to meet the needs of our customers in a highly competitive industry. We pride ourselves on delivering the highest quality with speed, integrity, accuracy and exceptional customer service.

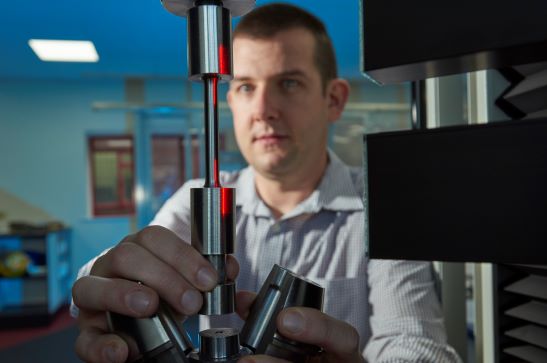

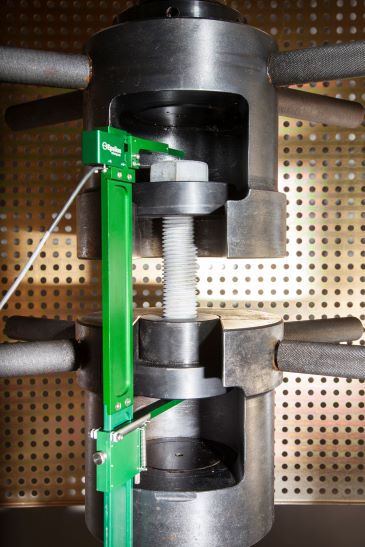

Our mechanical testing is carried out to the highest standard by experienced technicians. The laboratory is temperature controlled and all equipment is maintained and calibrated to national standards to ensure the integrity of our test results.

The following is a summary of our mechanical testing capabilities.

Tensile tests - room temperature

Tensile tests - elevated temperature

Impact tests - Charpy

Impact tests - Izod

Stress rupture tests

Hardness tests - Brinell

Hardness tests - Rockwell

Hardness tests - Vickers

Bend tests

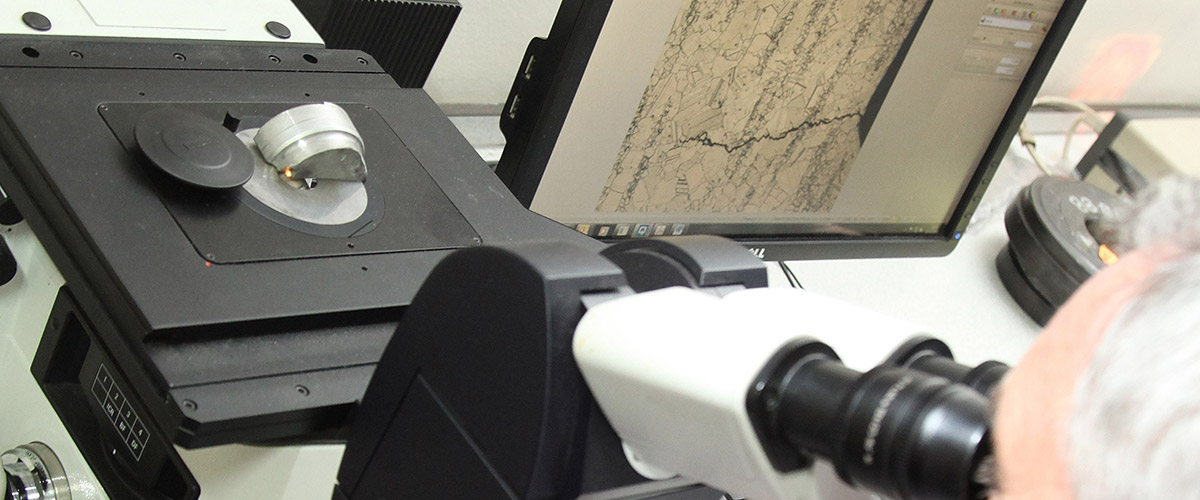

We are one of the UK’s leading laboratories carrying out metallurgical testing work for multiple industrial sectors including aerospace, oil and gas, biomedical, construction, power generation & automotive.

Employing degree qualified metallurgists and technicians, the department performs a comprehensive range of tests covering a wide range of materials, including titanium, aluminium, copper, carbon and alloys steels, stainless steels & high strength nickel alloys.

The following is a summary of our metallurgical capabilities

Our 1500kN tensile machine is dedicated to fastener testing and includes an Epsilon bolt extensometer that enables us to accurately determine the proof/yield stress of finished fasteners, as well as proof load measurements.

Our ever-expanding tooling collection enables us to test a wide range of metric and UN thread sizes.

Testing of Studs, Bolts and Nuts

We are accredited to test fasteners to National & International Standards made from a range of materials.

The chemical analysis department was established to complement the successful mechanical and metallurgical departments.

The following is a summary of our analytical testing capabilities:

We also use Leco and Eltra analysers to carry out gas determinations for carbon, sulphur, oxygen and nitrogen.

We offer a same day service for analytical testing by arrangement.

Understanding how materials behave in operating environments is essential. Using temperature controlled baths, we can test many samples simultaneously. Temperature control can be automated and recorded electronically if required. Hotplates are used to test materials in boiling solutions.

We perform a range of standard corrosion tests, including:

We have extensive machining capabilities that allows us to machine a wide range of sample sizes and material grades.

Our equipment, the quality controls we have in place, and the skill of our machinists, means we can prepare and test specimens from 3.99mm to 20mm section that are suitable for many sectors in our industry.

We have four dedicated furnaces for carrying out proof and post weld heat treatments. Two are calibrated to API 6A and two to AMS2750, required for heat treating to tight tolerances. We are able to apply oil or water quench with agitation to meet relevant standards.

Details of heat treatment applied to test pieces are included on our test certificates; we are able to produce and e-mail or print furnace charts thanks to the individual temperature recorder.

Our failure investigations service employs all testing methods available for full material examination to provide essential evidence in the identification of the cause of failure.